The role of optical fabrication in the electronics industry cannot be overstated. As technology continues to evolve at an unprecedented pace, the demand for precision and innovation in optical components has never been greater. Optical fabrication is the process of designing and manufacturing optical elements like lenses, mirrors, and prisms that are essential for various electronic devices. From smartphones and cameras to advanced display systems and optical sensors, the electronics industry relies heavily on the accuracy and versatility of optical components. This article explores the significant impact of optical fabrication on the electronics industry and how it contributes to the development of cutting-edge technologies.

What is Optical Fabrication?

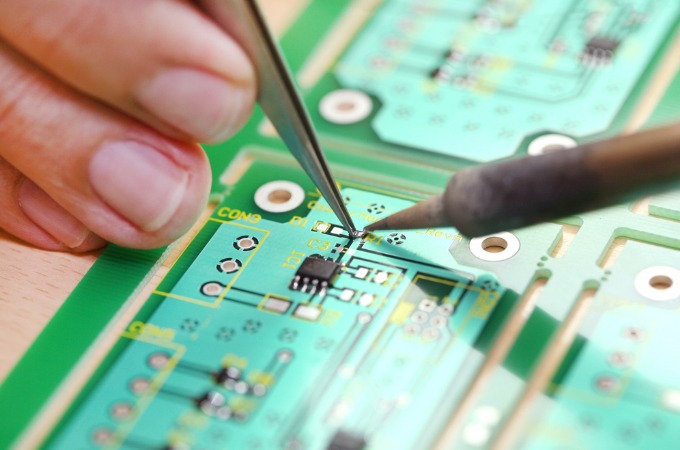

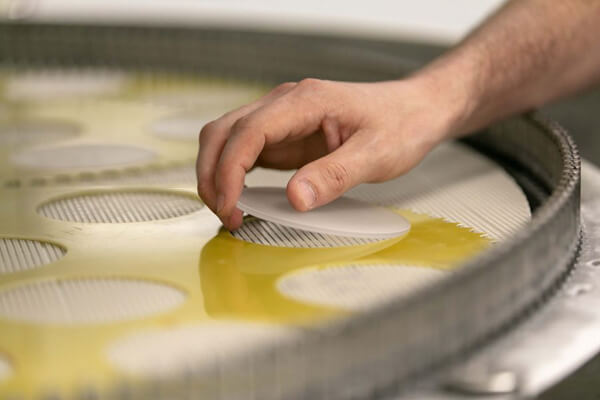

Optical fabrication refers to the precise crafting of optical components, typically made from glass, crystal, or other optical materials, to meet stringent design specifications. The process involves several stages, including cutting, grinding, polishing, and coating the material to achieve the desired optical properties. The goal of optical fabrication is to produce components that manipulate light in specific ways, enhancing the functionality of various electronic systems.

For example, optical fabrication is responsible for creating the lenses in cameras, the optical systems in sensors, and the mirrors in high-definition displays. These components are integral to ensuring the performance, efficiency, and clarity of modern electronic devices.

The Role of Optical Fabrication in the Electronics Industry

The electronics industry is driven by the constant demand for better, faster, and more efficient devices. As devices become smaller and more complex, the importance of precise optical components grows. Optical fabrication plays a key role in ensuring that these components meet the rigorous standards required for high-performance applications.

- One of the most significant contributions of optical fabrication is the development of advanced imaging systems. Cameras, for instance, have evolved significantly over the years, particularly in the smartphone industry. Today’s smartphones are equipped with highly sophisticated camera systems that rely on complex optical elements such as lenses and sensors. These components, which are fabricated with high precision, enable features like high-definition imaging, depth sensing, and augmented reality (AR).

- Similarly, optical fabrication is crucial in the development of optical sensors used in various electronic applications, such as medical devices, automotive systems, and environmental monitoring. These sensors rely on the ability of optical components to transmit and focus light accurately, ensuring that the sensors can detect specific wavelengths or light patterns. In fields like healthcare, for example, optical sensors are used for non-invasive diagnostics, where the precision of optical components directly impacts the effectiveness of the technology.

Advancements in Optical Fabrication: The Hyperbolic Lens

A key advancement in optical fabrication is the development of specialized lenses, such as the hyperbolic lens. The hyperbolic lens is an optical component with a unique shape that allows for better control of light in certain applications, such as high-performance imaging systems and lasers. The ability to fabricate these complex lenses with extreme precision is a testament to the advancements in optical fabrication techniques.

In the electronics industry, hyperbolic lenses are used in devices like microscopes, telescopes, and high-resolution cameras. These lenses help focus light in a way that reduces optical distortions and increases image clarity, which is crucial for applications requiring highly detailed visuals. As electronic devices demand more power and clarity, hyperbolic lenses and similar innovations continue to play an essential role in improving the quality and performance of imaging systems.

The Impact on Display Technology

Another area where optical fabrication has had a profound impact is in the development of display technologies. Modern displays, including those used in televisions, smartphones, and tablets, rely on optical components that are carefully fabricated to provide high-resolution and vibrant colors.

Optical fabrication ensures that these components are manufactured to precise specifications, allowing for better image quality and energy efficiency.

For example, liquid crystal displays (LCDs) and organic light-emitting diode (OLED) screens, which are widely used in electronics today, require advanced optical coatings and lenses to enhance brightness and contrast. The optical elements used in these displays must be manufactured with extreme precision to meet the stringent requirements of modern consumer electronics.

The development of flexible displays is another area where optical fabrication is making an impact. As the demand for foldable smartphones and other flexible devices increases, optical components must be designed to maintain their performance while also being flexible and durable. Optical fabrication is key to creating these innovative components, enabling the electronics industry to push the boundaries of display technology.

Future Trends in Optical Fabrication for Electronics

As the electronics industry continues to evolve, optical fabrication will become even more crucial in meeting the demands of next-generation technologies. Some key trends to watch include:

- Miniaturization: As electronic devices become smaller, optical components will need to be fabricated with even greater precision to fit into compact spaces without compromising performance. This trend is especially important in the development of wearable devices, where space is at a premium.

- Augmented and Virtual Reality (AR/VR): With the growing popularity of AR and VR applications, the demand for high-performance optical components will increase. These systems require sophisticated lenses and sensors to create immersive experiences, and optical fabrication will play a vital role in their development.

- Autonomous Vehicles: The rise of autonomous vehicles relies heavily on optical sensors and imaging systems for navigation and safety. Optical fabrication will be essential in producing the components necessary for these systems, including lidar sensors and high-resolution cameras.

Conclusion

Optical fabrication is a cornerstone of modern electronics, enabling the development of high-performance components for a wide range of applications. As the need for precision and miniaturization grows, the role of optical fabrication will only become more important. With innovations like the hyperbolic lens helping to push the boundaries of optical design, the future of optical fabrication promises exciting new possibilities for the electronics industry.